MRC offers a wide and professional range of Laboratory Glove Boxes for research and processing of air-sensitive materials and components under inert atmosphere . MRC also supply customized system solutions for thermal treatment, vacuum coating, operator safety and more. All MRC Glove box Systems are manufactured using the strictest of Quality Assurance measures and with only the highest quality components including Swagelok compression fittings and valves, Edwards Vacuum Components and Allen Bradley PLC Controls.

What are Laboratory Glove Boxes

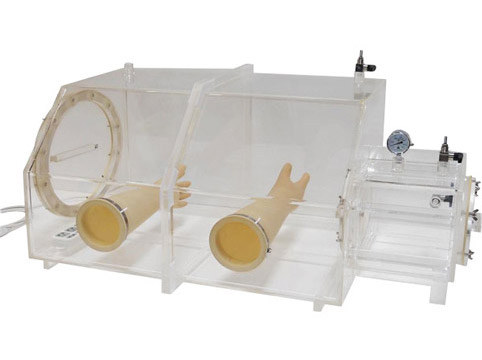

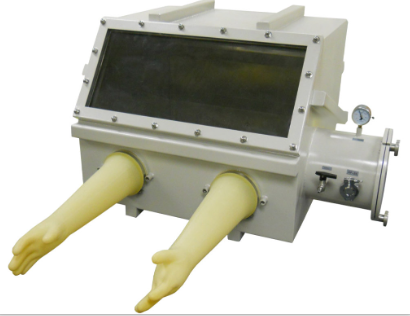

Glove boxes are Isolated chamber with arm ports or gloves. arm ports are arranged in such a way that the user can place their hands into the gloves and perform tasks inside the box without breaking containment.

Applications of Laboratory Glove Boxes

MRC glove box applications are:

-Personal Protection from hazardous substances

-Battery research

-Organic Electronics Organic light emitting diodes (devices)

-Additive Manufacturing

-Welding process in a controlled environment.

- Material Purification

- Thermal Treatment

- Perovskite materials research - solar cells

-Chemistry

-Stem Cell Research

-Microbiology

-Clostridium difficile

-Cancer Cell research

-Anaerobic research

-Life Science

-Clinical

-Coronavirus

-Pharmaceutical research

-Infectious Diseases

-Animal Research

-General Lab Studies

Types of glove boxes

-With gas purification system(for chemistry,batteries,Oleds, Perovskite)

-Inert gas,Argon or Nitrogen. (for chemistry,batteries,Oleds, Perovskite)

-Vacuum glove box

-Anaerobic glove box

-Laboratory Acrylic Glove Boxes

Best Laboratory Glove Boxes

MRC offers a wide and professional range of Laboratory Glove Boxes